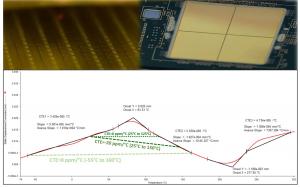

AI Technology, Inc. (AIT) launches its new lines of high melt-flow Build-Up Film Adhesive with 8-16 ppm/°C CTE

One of the critical properties of a successful Build-Up Film (BUF) dielectric prepreg adhesive is the ability to match the CTE of the core BT substrate (12 ppm/°C) and copper (18 ppm/°C) in minimizing the interfacial stresses while maintaining high melt-f

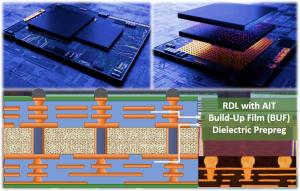

Build-up Film is the interlayer dielectric film that provides the interconnect for FC-BGA. With the 5G and chiplets applications, new class of BUF is required.

PRINCETON JUNCTION, NJ, UNITED STATES, July 11, 2023/EINPresswire.com/ -- AI Technology, Inc. (AIT) pioneered the first self-supporting epoxy film adhesives for both electrical and thermal conductivity back in 1980’s. The use of the self-supporting insulating epoxy and other crosslinked polymer film adhesive technology for build-up the core BT substrates for flip chip components started by Ajinomoto in 1990’s is now becoming critical substrate adhesive technology that enables the higher performance chip packaging and potential applications in the chiplets development. With the highspeed applications of 5G and developing 6G applications along with chiplets packaging that includes power devices, new class of build-up film adhesive prepregs with different performance characteristics are needed.AI Technology, Inc. is launching a new class of Build-Up Films (BUF) that expands and contract with low CTE of 8-10 ppm/°C (BUF 7883-FP) with silica CTE control and 16-18ppm/°C for higher thermal conductivity (BUF 7889-FP) with diamond fillers. There is also another series of new class of Build-Up Films with low dielectric constant of 2.6 to 2.8 with CTE below 18 ppm/°C for use in the highspeed chip integration and larger devices.

These new classes of Build-Up Films were developed with AIT’s proven modified cyanate ester film technology with engineered molecular stress absorption while maintaining its high glass transition temperature (Tg) of over 220°C. The same ambient storage, high melt-flow at lower pressure (15 psi) and lower melt-flow temperature (130°C and above) capability of the AIT modified cyanate ester film adhesive technology is incorporated in these new classes of Build-Up Films.

BUF 7883-FP and other Build-Up Film prepreg adhesives from AIT are supplied in thickness from 20μm and up with width of up to 20 inches on release liners.

The pilot testing by customers for high performance applications have been proven unparalleled in melt-flow and CTE controlled stress relief for large area devices. AIT has also recently established a new 18 acres headquarter campus facilities in Princeton near its Princeton Junction headquarters to house additional production lines to produce larger quantity of these Build-Up Films and other film adhesive products.

For more information on this new generation of Build-Up Film technology in helping to achieve your 3-D chips and chiplets design and reliability, please visit us at booth 1546 of SEMICON WEST 2023.

Maurice Lebron

AI Technology, Inc.

+1 6097998896

ait@aitechnology.com

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Electronics Industry, Military Industry, Telecommunications

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release